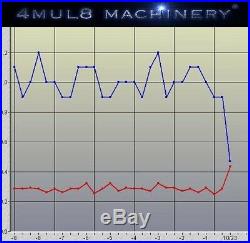

80 Cow Rotary Milking Parlor with Automatic Cup Puller + Milk Flow Meter. Delivered to your door! (Takes about 45 days). Quality milking parlors are absolutely essential for large dairy farms and milk-producing operations. Why 4mul8 Machinery ®? We offer included upgrades, installation and much more. This particular model features a round platform, an automatic pull-off, meaning that you no longer need to stand there while milking. This mechanism will automatically pull out the cluster, releasing it from the cow’s teat. The Automatic milk flow meter is an added bonus. We have had no issues with our machinery so far! Rest assured, you are in good hands! The most commercially utilized parlor installation to date is this type of milking parlor, for large producers. We offer a more economical, less-automated version as well, be sure to check it out! Standard concrete countertops have been used in the ranch industry. For more than 20 years, the design has been recognized as an industry leader by the turntable standards and has long proven to be the right choice for pastures in the US, New Zealand, Europe and many countries. The structure is robust and the engineering integration design makes the whole machine milking. The machine system is perfectly matched, and the convenient. Assembly design greatly improves the installation speed and. The 2.7 m wide countertop provides. Good protection for the milking equipment and electronics below. The design of the turntable provides the milker with a clean and smooth operation. With fast milking conditions, the flow of cattle on the upper and lower turns is very smooth and the milking equipment is at your fingertips. The direction of rotation of the turntable can be. Operator consoles, safety and protection devices are supplied with the turntable. Purchasing a 4mul8 Machinery® Turntable is a truly proven technology investment. The advanced design ensures that there are no additions and modifications to the site during installation. Any increase in equipment may seriously affect the compatibility of the turntable. This is worth reminding everyone. The platform facing the outer slope can ensure a strong structural design and provide sufficient space for the milking equipment under the turntable. Provide better cattle flow and smaller turntable diameter – smaller buildings mean saving construction costs. The milking system is installed under the turntable with a 1.8 meter space below the turntable for uncompromising milking performance. Clean and dry environment It is easy to maintain the milking system and reduce maintenance costs. New adjustable height and high strength steel roller Radial adjustment ensures accurate matching of the roller and the I-beam. The adjustable height is independently. Adjustable for fine adjustment of the left and right adjustment. Provides a sturdy, quiet, low-friction roller table that requires low-power turret drives. Are the basis for trouble-free operation of the turret. Heavy-duty rollers are laser-positioned and fine-tuned to perfection. The turntable has been running for decades. The perfect integration of the 4mul8 Machinery® milking system means that no design and processing work is required on site, each component is perfectly matched to maximize installation efficiency and protect the galvanized surface of the turret structure. The 12 degree inlet and outlet channels are designed to provide a smooth flow of cattle to and from the turntable. New design XP heavy-duty barriers The robust design can meet 24/7 continuous operation. Accurate processing and quality are very important for the turntable system. We are very proud of our precise processing and quality. Each part is produced by ourselves. In the factory, we use special tools to strictly control each process. All engineers have accumulated a lot of production experience, and the perfect combination of experience, technology and strict production technology ensures the perfect combination between each part of the turntable. We guarantee the life of the product, reduced maintenance costs and downtime. I-shaped steel is a very important structural component that constitutes the turntable. The special structure of round steel rail is the basis for reliable rotation of each turntable. Our precise process guarantees the. Each type of “I” steel is 100% accurate and calibrated, and the time spent on machining and precision manufacturing can greatly save installation and equipment operation and maintenance time. I-beams are molded to exact standards to ensure strength and durability. Special instruments are used to ensure that every part of the track is absolutely. Depending on the size of the turntable, 8-12 I-beam rails are typically required, each of which is a perfect combination to ensure continuity of the orbit. Each part of the track is measured by a laser level to ensure that each track is not distorted during processing. A 5-point measurement is made for each track to ensure continuity of the track radius so that each track is assembled to. Form a complete circle. The underpass is designed to ensure that technicians enter and exit the turntable center easily and safely. The 4mul8 drive unit is maintenance-free, and the light weight and high strength of the turntable design result in a very low power of the turntable drive motor. We always configure a spare drive unit just in case. In the event of a malfunction, you can switch the alternate drive by simply switching the valve. Countertop, teat set and railing flush. We offer countertops, teat sets and barrier flushing systems that automatically clean the milking system after the milking is completed. Hanging cattle exit device. We provide a device with two pieces of hard rubber to assist the cow to quickly exit the turntable. The cow’s back door makes it difficult for you to control the cows standing on the turntable. The back door is operated by a 75mm cylinder and is automatically controlled by the. If your cow does not finish ensuring continuous milking operations. 100mm cylinder diameter, the cup cylinder long as you gently hold the milk cup group state, you only need a single button. Milking cup set 320CC. Milking, the door will not be blocked. Lifts up, so that the cow will not exit the turntable in the exit area. It is not just a cylinder, but also a remote milking pneumatic device, as. In the milking state, the current milking point will automatically start. Robust but lightweight, PPSU food grade high-strength material, durable, resistant to. Large milk inlet and outlet to improve the vacuum stability of the nipple. Streamlined collection base for quick emptying of milk, easy one-handed operation by. Of the world’s most advanced diversion triangle milk lining to meet the needs of high. Smoother milk discharge, more effective protection of the cow’s breasts, effectively prevent the occurrence of mastitis. Drainage milk is faster and smoother. 320CC milk collector volume. For large diameter guide triangle milk lining. Sturdy, ergonomic milk collectors, is a very successful one on end during milking, ergonomically designed milk collector, milkman, greatly improves milking operation speed. The use for dairy cows is for rapid milk yield, faster and more efficient. The G2 cleaning tray is an excellent cleaning solution for the 4mul8 Machinery® milking system. The water flow can be adjusted according to the size of the equipment. A variety of cleaning cups can be selected, basically in combination with all cups and liners. The G2 cleaning tray is designed to ensure the hygiene and cleaning of the system. The milk pump is designed and manufactured according to European standards. The open impeller design is the best choice for the. The durable structure ensures long life and is especially suitable for equipment. The specially selected stainless steel alloy ensures trouble-free. Milk pump lift 110 m. Milk pump motor 2.2Kw, 400V 3 ph. Milk pump flow 20,000 liters. During the entire operation. Reliable Durable Less maintenance. The oil-free Luojing vacuum pump is designed for use in pasture applications with a vacuum pumping capacity ranging from 1000 to 11500 L/min. Equipped with a 120 liter vacuum buffer tank to prevent debris from entering the vacuum pump and providing a stable vacuum, ultra-quiet. The sounder provides a quiet milking environment for the entire milking operation. Confirmed reliable vacuum pump. Pumping capacity is 6000 liters / minute 50kpa. Low maintenance No oil Clean Environmentally friendly. 2 sets of circuits, 1 with 1 spare. The vacuum pump frequency converter is specially designed for this. The digital sensor is used to continuously monitor the vacuum and adjust the speed of the vacuum pump according to the continuous vacuum monitoring of the variable frequency for this oil-free positive displacement vacuum pump. The dynamic control vacuum. Fluctuation of the milking means. The fluctuation of the vacuum. Control system is well suited. Pump controller not only. Helps to improve the stability of the milking vacuum and reduces the energy consumption of the vacuum pump, reducing maintenance costs. The milk filter has a filtering capacity of 520 milking heads. If used for locations where more than 520 cows are milking, 2 or 3 filters can be connected in parallel. The rugged, heavy-duty filter housing ensures that the filter and seal will not deform and leak during use. The filters are manufactured to the highest standards in Europe and comply with current international standards. The 4mul8 Machinery® Center Rotary Pair turntable. The overall stainless double brush to facilitate. 63 mm milk connection. Completely separated power rails With 12 power rails. 4 silver-containing communication rails. 30 amp brushes (two per rail). External electrical connection box. Convenient service and maintenance. Unique adjustable support for installation accuracy. Can transmit power, communication, vacuum and milk to the steel design, all power and communication brushes are connected by uninterrupted power and communication connection. The operator can adjust the speed of the turntable, forward and backward, emergency stop button and stop/pneumatic button via the control panel, and the. Emergency stop and pneumatic & stop functions can also be activated via the red and blue ropes on the operator’s head. Turntable countertop control electric control box. All installation control equipment of the turntable is connected to this displayed here, which is convenient for timely solution. The inverter turntable according to the input command. If there is a fault that. The turntable is promptly exited from the turntable by the direct drive 2 sets of milk receiving tanks (operating independently on both sides). Receiving tank volume: 2x90Liters. Milk water separator volume: 2×60 Liters Milk pump power: 2.2 Kw. The type of fault can also adjust the rotation speed of milking. Milk enters the receiving tank from the top of. Tank, and the continuous liquid level control starts. The surge generator has continuous water injection and intermittent air intake during the cleaning process to ensure optimal tube. Piping and support system inside the turntable. For optimum hygiene and cleanliness and durability, all piping and supports are made of stainless steel, and cow lines, vacuum lines. And filtered air tubes are food grade PVC. Milk tube: 90mm stainless steel. Pulsating tube: 90mm food grade. Filter air tube: 90mm food grade. Cleaning tube: 50mm stainless. Inhaled a cup of lye to clean the internal particles. Maintenance is low and maintenance costs are saved. Energy consumption: 2X5.5W. Milking point controller MPC. The 4mul8 Machinery® Gold PMC milking point controller is designed for the harsh environment of large farms. Its electronic platform is designed to withstand long-term work with large motors, variable frequency controllers and other noise equipment. The new controller can be used in the wet environment of the milking parlour for a long time and is a very durable product. 4mul8 Machinery® milking point controller MPC serves as the operator interface for the milking machine management. System and the milkman. She can not only display the horn, milk output, milk flow rate for the milkman, but also display. In this case, if squeezed The milkman must be milking and need to press the milking button twice to milk. It also displays milking information for the current shift of the cow, for example: the conductivity is too high, the minimum value of the desired milk is not reached, and the milkman can also separate the milk of the current shift through the operation panel, as long as milking At the milking point, the input is required to separate the instructions. The current cattle will be separated before exiting the milking parlour. 4mul8 Gold Milk Meter. The 4mul8 Machinery® Milk meter has three measuring electrodes to provide enough access to the milk flow through the milk meter, except. In addition to measuring milk production, flow rate, and conductivity, the temperature of the washing water during the cleaning process can be measured to accurately monitor the actual cleaning effect of each milking position. Identification and propagation improvement system. The M-PD4 pedometer is a combination of the horn and the pedometer function, which is small and durable. Studies have confirmed that more than 2 million pedometer studies around the world have demonstrated a direct relationship between cow estrus and cow activity, and the 4mul8 cow estrus module measures the increase in cow activity through a. The 4mul8 Machinery® system accurately estimates the optimal fertilization time and simplifies and improves the reproductive management of the pasture. The 4mul8 Machinery® system can significantly increase the conception rate of cows, and it can reduce the number of days of cows through accurate cow estrus monitoring. The M-4B Blonde Monitoring System uses different types of pastures, can also be used for estrus monitoring of young cattle. The 4mul8 Machinery® Turntable Identification System has two identification sensors. Indicate the number of the bullpen. The other is installed at the entrance of the cow to sense the. Then, the 4mul8 Machinery® software is used to match the two numbers one by one to ensure the recognition system is very accurate. Over 99.5%, there is no estimated component. For example, captive or grazing, and. Sensor is installed in the position of the bullpen to cow entering the turntable. Pedometer numbers are based on accuracy of the cow identification. 4mul8 Machinery®’s compressed air system provides clean and dry compressed air for the milking machine system and the oxen door. System provides compressed air with a dew point as low as -80 degrees, ensuring trouble-free operation of the equipment during cold winter months. The intelligent cleaning system can be programmed according to the customer’s requirements and has been solidified inside the system. 20 standard step modules and more than 100 adjustable parameters, through the optimal combination of modules and parameters, can meet the cleaning and disinfection requirements of any farm. The intelligent cleaning controller can be cleaned and disinfected according to the seasons of the farm and the requirements of the milking operation. In order to facilitate the cleaning operation for different seasons and milking procedures, there are 4 cleaning programs on the cleaning controller panel. Key, you can press the required program button before cleaning, the whole cleaning will be carried out. According to the procedure you requested, thus ensuring the impact of different milking procedures and. Seasons on the washing and disinfection of the milking machine, ensuring the whole year. Automatically select, adjust the group, improve the efficiency of breeding work, and automatically divide the group after milking, so as to timely deal with the cattle that need attention every day. For example: veterinary treatment, pregnancy test, breeding, and many other cattle that need to be found. Two uses of the pedometer – cattle identification and activity measurement. 4mul8 Machinery®’s estrus monitoring module is based on scientific research confirming that there is a correlation between the amount of activity and the estrus. And after some improvements, the pedometer can accurately complete the estrus exposure work. The pedometer has a device for recording the number of steps, and sends the data to the estrus detection module of 4mul8 software to monitor the estrus of the cow. The pedometer’s components (with internal battery) are designed to be tied to the cow’s legs. A pedometer that is removed from a cow can be worn by other cattle, and the pedometer used for estrus is more economical. 4mul8 pedometer – a good tool for cattle estrus monitoring. Why does 4mul8′s pedometer become the most efficient and economical tool for estrus monitoring? The reason is that the pedometer is highly reliable and economical. 1992; Pennington (1986) reported that the artificial observation estrus rate was 45% and the pedometer. Observation estrus rate was 78% to 96%. Other studies have found that in the United States to test a variety of estrus methods, the cost of the pedometer is the lowest compared with waxing, estrus, and manual observation. The client confirmed that using the 4mul8 Blonde Test Module can improve the herd’s reproductive rate. According to statistics, after using the pedometer, the empty period of the cattle farm that relies entirely on the pedometer to monitor the estrus is reduced by an average of 13-25 days. An overseas client (South Africa) said: Since the beginning of the use of the pedometer, we have given up on manual observation of estrus, but every hair sensation will be prompted in the computer, so the pedometer is a good tool for large farms or small pastures. And can improve the breeding work of the cattle herd in a short time. Ranch management software and computer communication system 1 set of farm management software, milking module management software computer and milking parlor communication card. Network installation of herd management software. 4mul8 Machinery® software is the core of the Ranch Management System. Electronic devices such as electronic meters and pedometers are connected with 4mul8 software to transfer data to 4mul8 Software’s database. Store for long periods of time. The software is able to connect with all of 4mul8 Machinery®’s electronic components, receive data, and send commands to control hardware functions. The software can enable networking. Of multiple computers (up to 8 at a time). All data in 4mul8 software can be exported to an Excel spreadsheet and is compatible with Office Office software. All reports in the 4mul8 software can be printed directly from the printer. 4mul8 Machinery® Ranch Intelligent Management System Features. The featured software is the core of our ranch management system, through which the electronic devices such as electronic meters and pedometers are connected, and the data is transmitted to the software database for permanent storage. 4mul8 software is able to connect with all of 4mul8 Machinery®’s electronic components, receive data, and send commands to control hardware functions. 4mul8 software can realize the networking operation of multiple computers and support up to 8 computers. All data in the software can be exported to an Excel spreadsheet and is compatible with Office software. All reports in the software can be printed directly from the printer. 4mul8 Software is able to perform comprehensive herd management, including. Milking operation monitoring, early disease monitoring, abortion monitoring, estrus monitoring, etc. The 4mul8 Machinery® system accurately records the operation of the milkman, making it easy for farm managers to spot problems in the milking process. The milking station equipped with the 4mul8 Machinery® management system contains the automatic cupping function. After the cup is set, the electronic meter. Monitors the milk flow rate in real time. When the flow rate drops to the preset flow rate, the milking cup automatically takes off. Circumstances, cupping is done without manual intervention. The 4mul8 Machinery® system accurately records the cupping situation for each shift. If the cup is manually forced out before the end of the milking, such violations can be found through the 4mul8 system. The upper part of the figure in the picture shows the number of abnormal cuppings (manual forced cupping) for each milking shift. The shifts 1 and 2 are more. Than 30 times, which is similar to the past, but the shift 3 suddenly increased to 54 times, indicating that there is a problem with shift 3. Check the flow rate of each cup of abnormal cupping to find out which milking position is too early to remove the cup. Early monitoring of mastitis. 4mul8 Machinery®’s electronic gauge not only accurately measures milk production, but also finds mastitis cows by measuring the conductivity of milk. The conductivity increases, indicating a breast infection. When a cow is in estrus, it becomes irritated and runs around. Therefore, the amount of activity data collected by the pedometer will increase significantly. 4mul8 software automatically screens these cows from the herd and lists them in the estrus list. The figure below is a graph of the activity of the estrus in the last 10 days. While the activity curve has risen sharply, the milk production efficiency has also dropped slightly. This is the most typical performance of the estrus. Reproductive disease surveillance – follicular cyst. Some cows can’t be bred, such as cows with follicular cysts. Through the 4mul8 Machinery® system, we can find such cows and avoid wasting frozen sperm. The figure below shows the first four estrus curves of bovine 6467. The estrus interval is only half of the normal interval and is a typical symptom of. Such cows cannot be bred even if they are estrus. As the milk production of dairy cows continues to increase, the chances of developing reproductive disorders will increase. Long-term unestrusing cattle bring great trouble to breeding work. Through the amount of activity data collected by the 4mul8 Machinery® system, we can easily find the ill-fated cattle. The figure below is a graph of a non-estrus cow. The activity curve of this cow is very stable within 117 days after calving. There is no estrus, which is abnormal and needs to be treated as soon as possible. Pregnant cows are not estrus, once estrus, this cow has been aborted. The pedometer closely monitors changes in the activity of pregnant cows and alerts the system once a cow that may be aborted is found. Monitoring foot and hoof disease. When the cow’s limbs have problems, its activity will drop. By monitoring the cattle with reduced activity, we can find out the cows with limbs and hoof problems (such as limbs and foreign bodies). The activity of the cattle shown in the figure below is very low and irregular, and there may be problems with the limbs. 4mul8 software can comprehensively monitor and manage the work of milkers, breeders and veterinarians. After the cup is set, the electronic meter monitors the milk flow rate in real time. Under normal circumstances, cupping is done without manual intervention. The upper part of the figure below shows the number of abnormal cuppings (manual forced cupping) for each milking shift. The shifts 1 and 2 are more than 30 times, which is similar to the past, but the shift 3 suddenly increased to 54 times, indicating that there is a problem with shift 3. We can also check the flow rate of each cup of abnormal cupping to find out which milking position is too early to remove the cup. The breeding report (by breeder) is a self-contained report from 4mul8 Software that compares the number of jobs and pregnancy rates of individual. Veterinary treatment effect monitoring. The following is an example of how to monitor the efficacy of mastitis treatment to show how to monitor the work of the veterinarian. Finding mastitis is only the first step in the long march, and more importantly, how to cure sick cows as soon as possible. The 4mul8 Machinery® system provides a very simple tool that allows farm managers to easily understand the treatment of the disease. The software can record the detailed information of prescriptions and symptoms of veterinary treatment in detail. At the same time, combined with the recovery of the treatment after treatment, it is very easy to judge the therapeutic effect. The cows in the picture below suddenly became infected with mastitis on the 20th day after birth (increased conductivity, decreased milk production). Mastitis treatment effect tracking (If treatment effect is not good). 4mul8 software comes with more than 120 professional reports and charts that can be printed directly. The following is a summary of these reports: Common reports at headquarters. Online version management system, monthly milk production report, daily milk production. Report, milk ingredients (daily), milk sale list. Common report of the Animal Husbandry Bureau. Monthly quarantine immunization summary, monthly morbidity report, phase-out situation (cause), phase-out situation (detailed report), phase-out situation (type). Report that must be seen by the person in charge of the ranch Herd overview, whole cattle distribution. Herd summary (by month), calving and survival rate, elimination summary, reserve cattle measurement, reserve cattle daily weight gain. Reproduction supervisor must see report. Breeding index, breeding daily event summary, expected calving summary, expected calving, expected milking, reproduction report (total), reproduction report (by breeder), reproduction report (by bull). The breeder must see the report daily. Today’s cows, estrus curves, estrus interval of normal estrus cattle, estrus interval of ovarian cyst cattle, estrus plot of cattle, cows that need pregnancy test today, reserve cows this month, 180 days after birth Pregnancy cattle, 90 days postpartum unfed cattle, frozen sperm inventory, suspected abortion, abortion cattle activity curve, pre-production (today), expected to stop milk (today). Milk production management report. Milking days distribution, fetal milk production curve, average parity output, DHI test results, somatic cell trend, station report (milk composition), milk composition curve milking station monitoring report Abnormal milking (premature cupping), abnormal milking (excessive milking), lactation curve, cup sequence, milking cow detailing. Veterinary Supervisor must see report. Veterinary daily event summary, diagnosis summary, treatment summary, drug summary, drug in and out, drug inventory, drug consumption list. Veterinary daily must-see report. Health monitoring report (1 deviation report), graph of mastitis cows, tracking of mastitis treatment effect (treatment is not timely), mastitis treatment effect tracking (treatment timely), digestive disease curve, limb and hoof disease curve, Summary of clinical mastitis and sputum area, suspected acidosis cows, suspected ketosis, suspected ketosis curve, all cows in the sputum area, blood milk monitoring report, platform report (land). Schedule: Safety stock and wearing parts for 50-position turntable equipment. Control panel D type interface cable. Cup / vacuum switch – solenoid valve. (negative pressure + positive pressure). Milk pump check valve. Special cleaning agent for milking equipment – acid. Special cleaning agent for milking equipment – alkaline. American nipple medicated bath spray gun. Milking parlor maintenance special tools. Milking operation and maintenance, software use. Third year, 80% in the fourth year. 20% in the fifth year. After sales service for life. After the equipment is in operation, the service engineer will prepare a service plan for the customer in advance and go to the site to carry out maintenance and maintenance of the equipment system to prevent failure in advance. Response service: 24-hour telephone and network response, response time 2 hours, and processing within 24 hours. After-sales service: Once every 2 months (6 times a year) on-site system (software and hardware) overhaul, pasture production technology. After each service, issue service reports and suggestions, such as: overall equipment operation, consumable parts. Milking hall hygiene and management recommendations emergency drills, production management recommendations. If a goat milking parlor is needed, please specify while purchasing. Yes, every item mentioned is already included and this is all that you need to start milking your cows or goats. We can offer grinders and mills as well, just ask! Investment return recommendation: According to our previous experience, the complete system of cattle of different scales will recover the. Investment cost in the case of correct use for 10 to 20 months. 30 years of scientific cattle breeding experience and mature and effective production. These units help the pasture to achieve long-term maximum profitability of the system engineering. As always, Excellent Customer service available around the clock to serve you. UK and most of Europe – 22-27%. Normally it is 5% or 10% of our cost, not yours. You can be assured that your order is in good hands, and will feel satisfaction in knowing that you have ordered top-quality machinery from a transparent supplier, who puts customers first. We have already thought of the upgrades before you ask for them. We offer all the bells and whistles at an affordable price, to keep it simple. Now I ask you, why 4mul8 Machinery ®? All factory defects are taken care of by us! The item “4mul8 Machinery Auto Rotary Milking Parlor 80 Cows Puller + Flow Meter” is in sale since Sunday, December 29, 2019. This item is in the category “Business & Industrial\Agriculture & Forestry\Livestock Supplies\Dairy Cattle”. The seller is “qualitycounts403″ and is located in Calgary, Alberta. This item can be shipped worldwide.

- Model: RMP- 80A

- Custom Bundle: Yes

- Bundle Description: Automatic Puller Automatic Milk flow meter Intelligent milking system Delivery Installation Warranty Duties paid for USA and any country with a 0% duty on agricultural and dairy machinery.

If you like this post and would like to receive updates from this blog, please subscribe our feed.

If you like this post and would like to receive updates from this blog, please subscribe our feed.